What are the advantages and disadvantages of different forms of hydrogen carriers? And for which applications are which forms suitable? This was discussed on Thursday 13 February during a well-attended H2 Knowledge Café. In addition to a lot of technical knowledge, a remarkable plan was also presented for the construction of a biomethanol factory in Alkmaar.

For this edition of H2 Kenniscafé we were guests at InVesta in Alkmaar, where Frank Brandsen (New Energy Coalition) acted as host. Pointing to the full room (approximately 60 visitors, registration had been closed for weeks), he noted that the energy transition is very much alive. A good sign, as far as Brandsen is concerned. But a lot still needs to be done to achieve the climate objectives. Not only does the electrification of the energy demand need to be further implemented, far-reaching greening is also necessary when it comes to the use of fuels. Brandsen: “In the long term, we want to move towards 50% renewable. And hydrogen plays an important role in this.

Richard Engelkes from AYOP (Offshore Energy Association) opened the evening with an introduction to the offshore sector. In particular, he discussed energy production with large wind farms that are located far from the coast. Due to the loss in transporting electricity over long distances, it is advantageous to produce hydrogen at sea and to land it via gas pipelines.

To allow electrolysis to take place at sea, various concepts are being developed: in windmills, on ships and on energy islands to be constructed. According to Engelkes, the latter option in particular offers advantages for various reasons, with the added bonus: “Islands that are also suitable for producing food.”

With its own production, the Netherlands can partly meet its own needs. But even if all ambitious plans with the construction of wind farms off the coast are realized, imports will remain necessary, says Ellen van der Veer of ECOLOG. In her presentation she gave a clear overview of the forms and applications of hydrogen carriers. Strongly summarized:

Van der Veer also anticipated the possibility of storing and transporting hydrogen by using hydrogen to merge (Lh2). This happens at a very low temperature and requires a lot of energy, which unfortunately is lost in the transition from liquid to gas. A shame, but here too, smart solutions are conceivable. Van der Veer talked about a project she is closely involved in, which is aimed at reusing the cold released during the gasification of LH2 for the liquefaction of Co2 (for export to Norway).

Investa is an incubator for green gas technology where Sustenso (biomass fermentation) and DOPS (recovering raw materials from waste) are part of. Both have found each other in a new initiative: an advanced factory that will produce sustainable methanol and high-quality carbon from organic waste streams.

The plant uses DOPS' patented technology, which enables the conversion of biobased waste, such as waste wood, dried sludge, plastics and digestate (the residual product from Sustenso's digesters) into hydrogen, carbon monoxide and solid carbon. Hydrogen and carbon monoxide are easily converted into biomethanol.

Because there is no electrolysis in this process, according to Michel Spits (DOPS), it is possible to produce hydrogen at very low prices. Spits is aiming for a sales price of 2 euros per kg. The factory that will operate under the name Energy Greenery Alkmaar will be located near Investa. Construction is scheduled to start in 2027, after which production can begin from 2028-29.

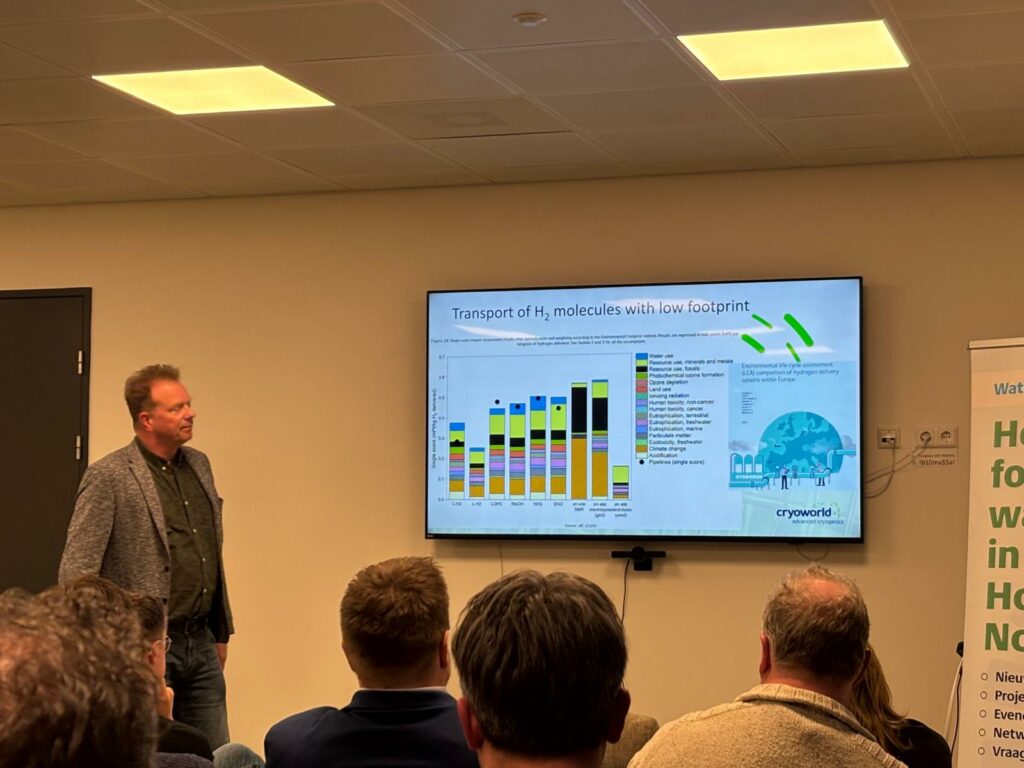

The evening ended with Cryoworld, a global player in the region in the field of liquid hydrogen (LH2). In general, liquefaction of hydrogen is seen as a solution to transport large volumes of hydrogen in an economically viable way over long distances. At the destination, it is converted back into gaseous form. “But why would you gasify,” wondered technical director Marcel Keezer. Especially where energy consumption is high, it offers advantages to use liquid hydrogen.

An example is heavy mobility, but also construction machinery, shipping and aviation. An additional aspect is that much less traffic is needed to supply petrol stations; instead of 16 trailers with gas cylinders, one trailer LH2 is sufficient. Keezer: “LH2 is a fuel for thirsty users.”

H2 Kenniscafé is an initiative of Waterstof NHN. Do you want to stay informed and participate in the discussion about the hydrogen economy in North Holland North? Then register as a community member. The next knowledge café is planned for Tuesday 6 May, location and theme will follow soon.